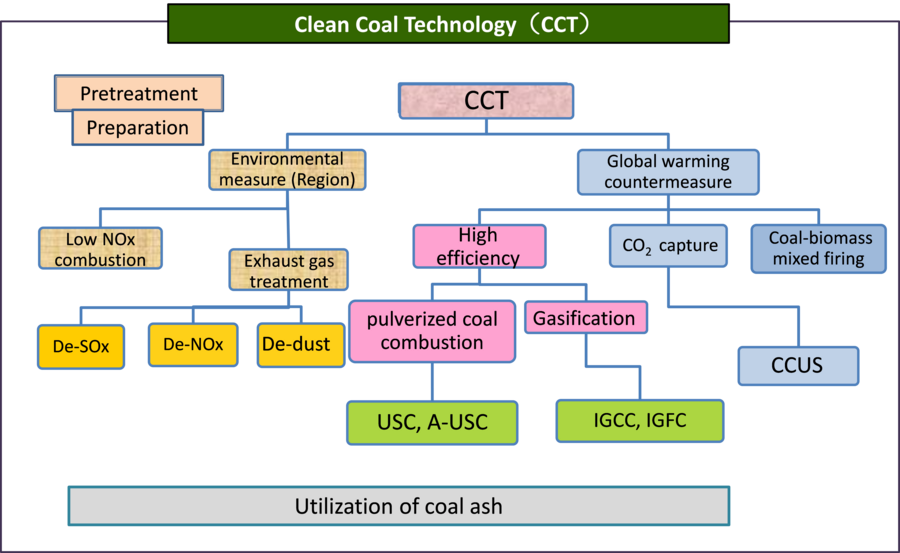

Promotion of Clean Coal Technology Development

Promotion of CCT development such as high efficiency of coal fired power plant and zero-emission technology is required to reduce the greenhouse gas emitted from the power plants. Global energy demand is on a solid upturn, the technologies for using low-rank coal--which accounts for about half of total coal resources--are also critical from the viewpoint of energy security.

JCOAL appreciates the environment of coal, investigates and suggests solutions to coal-related issues, and develops technologies to protect the environment and to enable the use of low-rank coal from the medium- and long-term perspective.

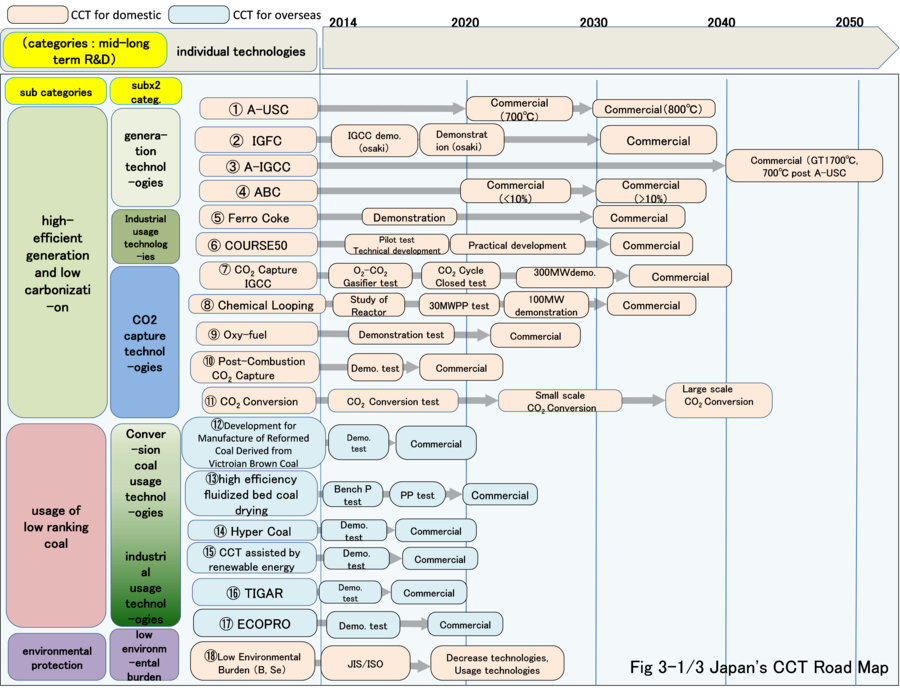

1. Technology Development Committee and JCOAL/CCT Road map

JCOAL has organized the Technology Development Committee, which support to achieve and prove elemental technologies early on in their development on a medium- and long-term basis. It also aids in setting new issues and launching new projects to facilitate commercialization by consolidating the needs of members and sharing related information and data. The committee draws up and--in accordance with revisions of the Strategic Energy Plan--regularly updates the JCOAL/CCT roadmap that guides future technology development.

2.CO2 Separation Emissions Reduction Technology

(1)Results and Future Prospects of the Oxyfuel Project

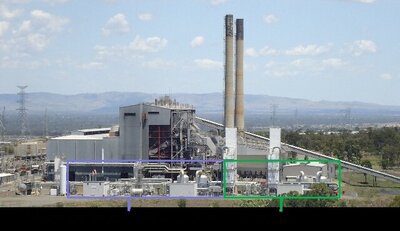

The "Callide Oxyfuel Project"--a joint venture of the governments and peoples of Australia and Japan aimed at achieving zero emissions in coal-fired power plants--successfully completed its demonstrated operation in March 2015. On the Japanese side, this project was joined by the Electric Power Development Co., Ltd., IHI Corporation, and Mitsui & Co., Ltd.--all members of JCOAL--while the project was subsidized by the Ministry of Economy, Trade and Industry (METI). The purpose of this project is to verify the reliability and operability of an integrated CCS system based on an Oxyfuel power generation system through the actual operation of equipment connected to an electric power system. The demonstrated test was conducted in Unit A4 of the Callide A Power Station in Queensland, Australia. Built in the 1960s, this station had been shut down due to deterioration when the project was initiated, but it was renovated to implement the oxygen fuel technology. The project exhibited the applicability of the leading-edge oxygen fuel technology to a degraded, out-of-date power plant, proving its high adaptability.

As a supporting collaborator, JCOAL provided support for this project and also conducted a desk-top chemical reaction test of CO2 recovery and storage (CCS) achievement and a laboratory experiment to determine the reaction of injected CO2 with rock in the reservoir and shale in the sealing layer. The Oxyfuel technology uses oxygen separated from air for coal burn. High purity nitrogen is obtained as by-product, which can increase economy if it is applied to resource development or industrial plants. With the abovementioned three Japanese firms, JCOAL investigated the feasibility of CO2 capture/utilization/storage (CCUS) in Alberta, Canada, with the support of the New Energy and Industrial Technology Development Organization (NEDO) as a step to commercializing the technology. We will support to promote the oxyfuel combustion system in cooperation with our member companies.

(2)Technology Development of Chemical Looping Combustion of Coal-with Carbon Dioxide Separation

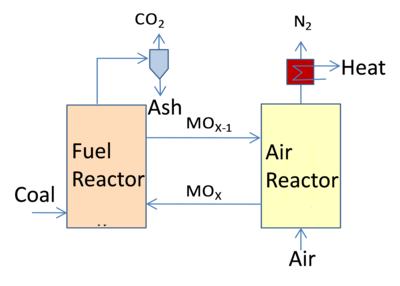

Chemical looping combustion (CLC) can be used for high-efficiency combustion of coal with CO2 capture. During CLC, coal is oxidized by an oxygen carrier, usually a metal oxide, in a fuel reactor (FR) with the aid of steam. Then the reduced oxygen carrier is oxidized by air in an air reactor (AR).

Based on the results of a NEDO survey project conducted from fiscal 2012 to 2014, which included trends in chemical looping technology development, identification of associated market, development issues, development objectives and practices. Then, a full-scale project for the development of technology for the chemical looping combustion of coal with CO2 separation was launched in 2015 and set to run for six years. The ultimate objective of the six-year technology development is to build a coal-fired power generation system with a separation and capture cost in the 1,000 yen/t-CO2 range, with the plan for the first three years to include bench-scale experiments (100kW) together with studies into the selection of oxygen carrier, process configuration conditions, and economics and market. The plan for the final three years is to resolve the issues, including PDU testing.

(3)A long-term demonstration aiming at reduction of CO2 emission by multi-material bio-coke

The gasification melting furnaces method for general waste treatment facilities that can achieve high environmental ability and ash volume reduction are prevalent in Japan. The bio-coke made of various biomass that is carbon-neutral new fuel, is fed into the furnace for several months to substitute coal coke and verified to reduce CO2 emission with no less than 25%. The objectives of this project are as follows.

1)To perform the steady collection of necessary biomass in Yokote city, Akita prefecture. The both of rice husk and bark are expected to be main materials of bio-coke, however according to the harvest season and snow fall season respectively, these generation quantity are greatly changed. In order to keep the quantity throughout the year, various available biomass shall be collected and mixed, consequently used as multi-material feedstock for bio-coke production.

2)To develop the production technology of multi-material bio-coke with effective and economic way.

3)To demonstrate the long time operation using bio-coke at Morioka/Shiwa District Environmental Facilities Association.

4)To investigate the applicability of multi-material bio-coke to other industries.

(4)Development Status Survey and International Collaboration regarding the Technology of CCUS

A CCS technology study and a survey of innovative CCS (Carbon dioxide Capture and Storage) technologies have been conducted under contract to NEDO since fiscal 2014. This involved looking at current progress and the level of development of post-combustion, pre-combustion, and oxygen combustion CCS technologies in Japan and elsewhere, and making a more detailed evaluation of promising technologies from among these that will be able to be used on a commercial scale in the near future.

The practical realization of CCS technologies will be essential to the future achievement of zero-emission coal-fired power generation. Because CCS technologies are currently expensive and consume a large amount of energy, the development of core technologies for commercialization and the running of demonstration projects in preparation for practical realization are taking place in various parts of the world. JCOAL is involved in an oxygen combustion CCS demonstration project in Callide in Australia, a feasibility study into its practical realization in Alberta, Canada, and a feasibility study of post-combustion EOR using amine solvents in Saskatchewan, Canada. In addition to collaborating with IEA/GHG and the Global CCS Institute (GCCSI) to jointly host an international conference on CCS, JCOAL is also boosting activities aimed at the practical realization of CCS by promoting knowledge sharing to encourage work on implementing CCS at an international level.

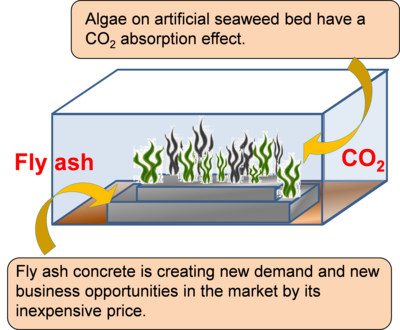

In addition, JCOAL progresses CCUS business model that CO2 utilization technology for the algal culture in the sea area.

3.Technology Development for Conversion of Unused Coal into Useful Resources

(1)TIGARⓇ (Twin IHI Gasifier)

Aiming at the commercialization of low-temperature, atmospheric-pressure, circulating fluidized bed type gasification reactor technology (TIGAR) for producing chemical material gas from lignite in Indonesia, IHI has carried a test with 6 tons/day pilot plant to collect data for a demonstration project and feasibility study. IHI has built a 50tons/day demonstration plant in Indonesia and continues to perform the demonstration test to collect data for checking the operation performance for the commercial use since 2014. JCOAL has been helping with market research and technology research for this demonstration project.

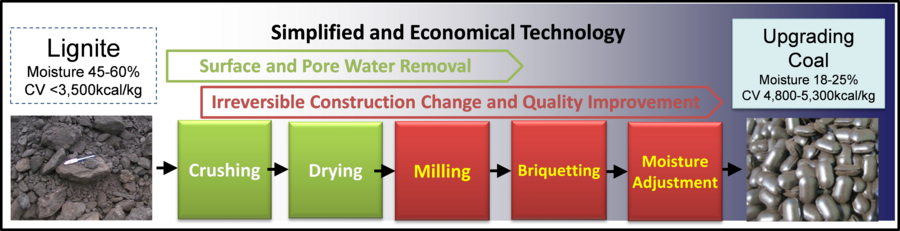

(2)Quality Up-grading Technology

In the Indonesia, UBE Industries, Ltd., Tsukishima Kikai Co., Ltd. and JCOAL develop the technology which realizes the lignite upgrading business of producing high quality briquette with the equivalent handling performance to subbituminous coal, such like prevention of powdering, spontaneous combustion and moisture re-absorption. Using the upgrading coal with lower ash and sulfur content coming from the Indonesian lignite original property is expected to reduce environmental impact in the use at the coal-fired power plant. The new business model optimizing the value chain from mine to final customer is also under development.

(3)Multipurpose Use of Low-rank coal

With low-rank coal, there is a need for measures to prevent spontaneous-heating, temperature rise, and combustion at the mine, during shipping, and at the power plant, steel mill or other end user. JCOAL has since 2014 been discussing this issue through a study group and volunteer member working group, including a survey of measures to prevent spontaneous-heating. Based on the results of this work, a three-year NEDO project on spontaneous-heating was launched in 2015. The major activities of the project are the development of methods for accessing coal for how likely it is to spontaneous-heat and the development of simulation techniques.

4.Technology Development for Efficient Use of Coal Ash

(1)Nationwide Fact-finding Survey into the Efficient Use of Coal Ash

With the cooperation with general industrial companies, JCOAL has been conducting nationwide fact-finding surveys. JCOAL has been carrying out a questionnaire-based investigation of general industrial companies that have coal-fired boilers equipped with power generation facilities with outputs of 1,000 kW or more to collect data on the volumes of coal ash produced and utilized as well as the utilization methods, and to focus on their secular changes.

(2)Guidelines

In cooperation with the National Institute for Environmental Studies and the Port and Airport Research Institute, JCOAL developed and published the Guideline for Utilization of Coal Ash Mixed Materials for Port and Harbor Construction Work and the Guidelines for effective utilization of coal ash mixed material (Earthquake disaster reconstruction) as guidelines for using a coal ash-based mixture comprising coal ash, a little cement, and water. These guidelines are designed to facilitate the use of coal ash in harbor works and as a material for reconstruction work in areas destroyed by the Great East Japan Earthquake.

(3)Study for Production Technology for Geopolymer, Non-cement Fly-ash Concrete

Working with Central Research Institute of Electric Power Industry, JCOAL is researching a method for solidifying coal ash through the addition of alkali additive. The aim of this effort is to develop technologies for using coal ash that is not suitable for mixture with concrete under the Japanese Industrial Standard (JIS).

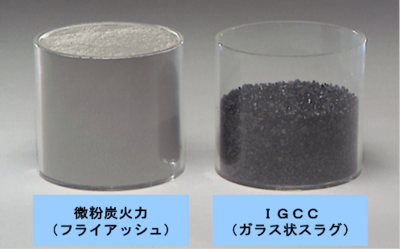

(4)Utilization of Coal Gasification slag

Integrated coal Gasification Combined Cycle (IGCC) is new technology with lots of attention in recent years from the view point of reduction of various environmental impacts. In this system, ash content of coal after gasification process is made into the form of slag instead of coal ash. The slag has large potential of effective use in concrete material field. JCOAL promote the standardization of this slag for valuable industrial products and also for the diffusion of IGCC Power System together with TEPCO, Energia, JPOWER, Jyoban Joint Power and OSAKI Osaki Coolgen.

(5)Utilization for marine structure (e.q. artificial reef) and cooperation with CO2 reduction

JCOAL is investigating the generation of high quality artificial reef made by coal ash admixture materials. This leads to the protection of marine resources and also hopes to reduce CO2 with growing seaweed forest on the artificial reef.